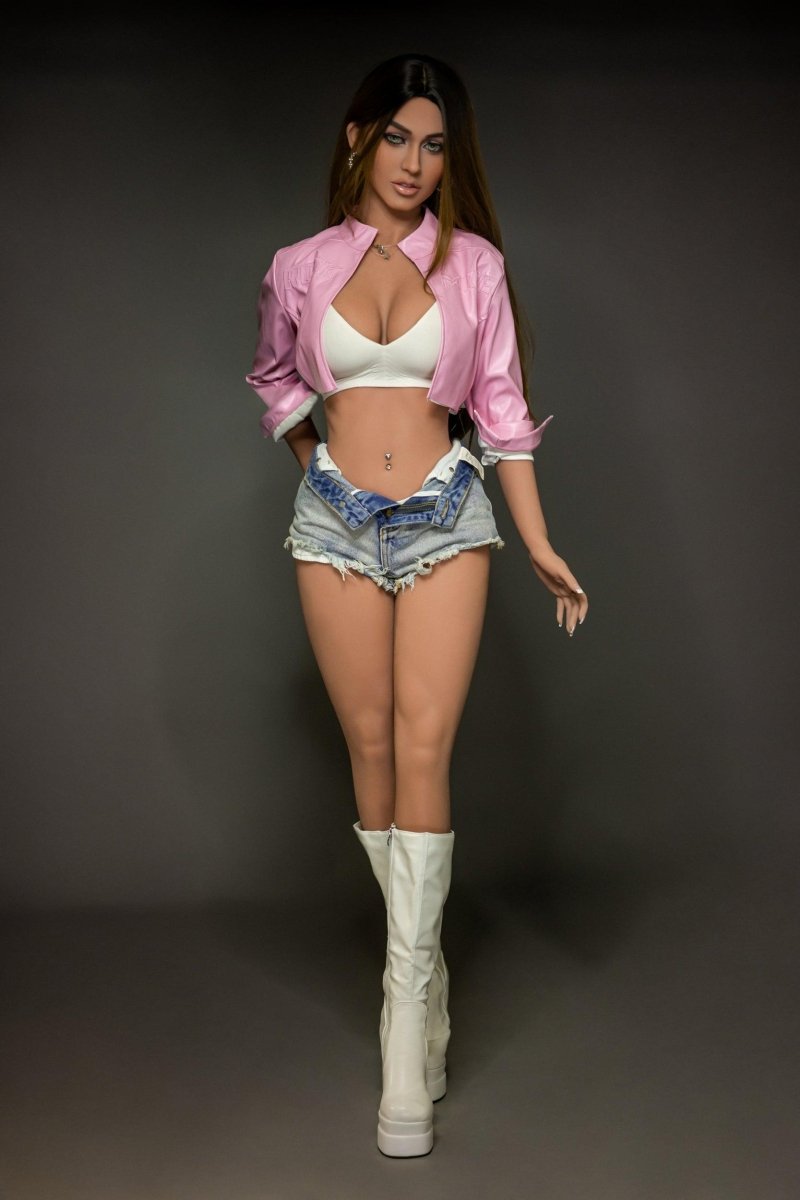

WM Doll STPE material description

Understanding TPE Material Technology in Modern Silicone Crafting

Introduction

High-end life-sized figurines and realistic models today often use a material known as TPE (Thermoplastic Elastomer). This advanced compound blends flexibility, softness, and resilience, offering a lifelike texture that’s also durable and easy to maintain.

1. What Is TPE?

TPE is a hybrid polymer that combines the elasticity of rubber with the recyclability of plastic. It’s widely used in industries such as medical devices, robotics, and special-effects modeling, where both realism and safety matter.

2. Advantages of TPE Material

-

Soft and flexible feel: Provides a realistic texture suitable for lifelike modeling.

-

Durability: Resistant to tearing and long-term deformation.

-

Safe composition: Free from common harmful substances such as phthalates.

-

Temperature adaptability: Can withstand a wide range of environmental conditions without cracking or stiffening.

3. Comparison with Silicone

While silicone is known for firmness and heat resistance, TPE offers superior elasticity and a softer touch. Each material has its own use case — TPE for flexibility, silicone for structural precision.

4. Maintenance Tips

To extend the lifespan of any TPE-based product:

-

Keep it clean and dry after each use.

-

Store away from direct sunlight or high temperatures.

-

Use compatible maintenance powders or conditioners to preserve the texture.

5. The Role of Material Innovation

Manufacturers like WM Doll are investing in improved TPE formulations that increase durability, color fidelity, and tactile realism. Continuous R&D ensures the material remains at the forefront of high-quality manufacturing.

Conclusion

TPE material represents a breakthrough in flexible realism. With proper care and thoughtful engineering, it ensures products that are both visually appealing and built to last.